About Us

About Us

GBT COMPOSITES TECHNOLOGY LTD started its operating in 2009 to develop and manufacture performance composite parts. The company is located in Baroda, Gujarat western region of India ideally positioned to provide service all over Asia, US and European markets.

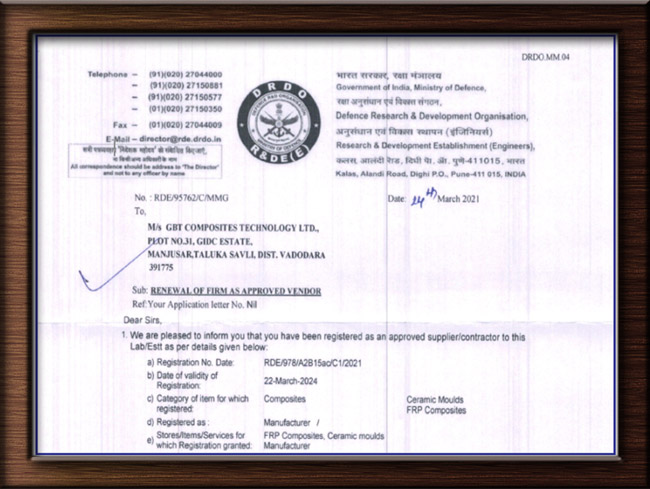

GBTC has supplied the composite parts with its expertise to several industries; these include Wind Energy, Defense, Automotive, Aerospace, Railways, Marine, Electrical and Domestics. GBT has historically been well known for its strength in Composite Moulds, Tooling's and Part production that goes above and beyond the expected, and being responsive to customer needs.

We are setting up a highly efficient environmentally friendly production based on innovative manufacturing techniques. We have complete set up from Design, R&D to Manufacturing at our Baroda Facility. Our core team is constituted by very rich experience in composites and electromechanical tooling’s with a collective experience of above 50 years. Our mission is to achieve leadership in production, sales and engineering of the new generation of composites on GLOBAL market.

Mission and Vision

The aim of GBT Composites Technology Ltd. Is to be globally known Design & Manufacturing organization of Composites Tooling, Composites and Metallic Components.

Expertise

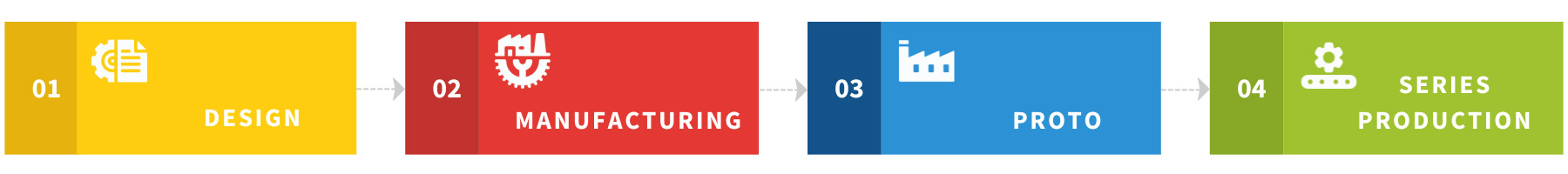

Our Management & Core Team is constituted by rich experience in Composites and electro-menchanicaltoolings with collective experience of above 50 years. We have muscled our strength and abilities to offer intelligent, Innovative and Instant solutions in the field of Design, Manufacturing, Proto-typing and Series Production.

Our expertise is to build the plugs and moulds for all composites components. The plugs with base steel structure and top surface will be CNC Milled. The moulds are produced with integrated Electrical Heating System and Vacuum infusion system. The moulds will be provided with all kinds of markings to ensure constant lay-up of materials and finishing. We ensure CTE for Long life of the Moulds. We have in-house capability to design and manufacture Jigs and fixtures for various applications in component production. We provide the moulds with excellent world class Electro-mechanical toolings with sophisticated data acquisition & control systems. The software for the same is being developed by team of experts under our guidance.

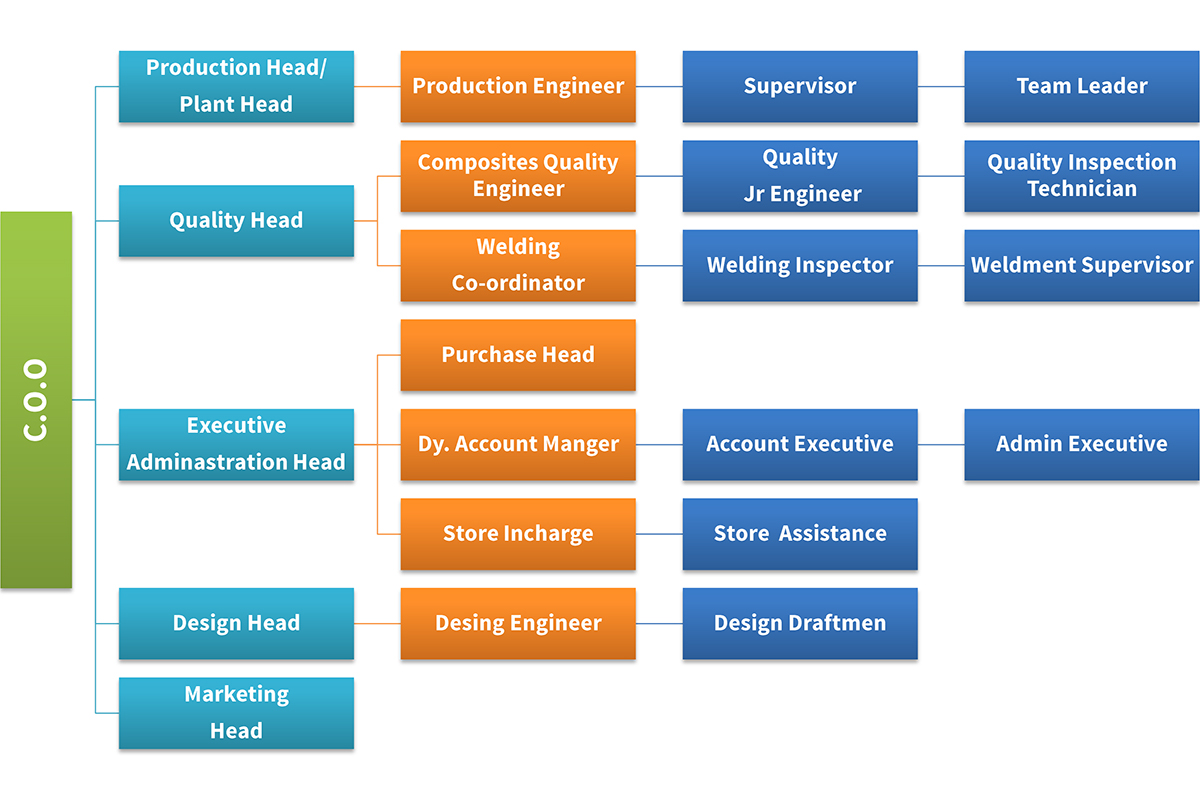

Core Team

Mr. Mehul Patel

Chief Operational Officer (C.O.O)

Mr. Dharmesh Tandel

Head of Production

Mr. Sistu Prabhakar

Head QA/QC, Projects Leader

Mr. Pradeep Nayak

Manufacturing-Shop Floor leader

Mr. Jigar Patel

Purchase /Production (Welded Components)

Mr. Priyank Barot

Design & Development (Composites)

Mr. Hardik Patel

Design & Development (Welded Structure)

Mr. Vidhyut Patel

Head of Solar Division

Organisation Structure