Infrastructure

Production Capabilities & Expertise

Metallic Manufacturing Process

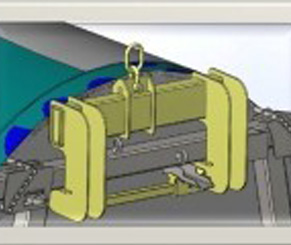

Auxiliary and Electro Mechanical Tool

GBT composites HAVE COMPLETE SOLUTIONS FOR THE metallic auxiliary, finished and electro mechanical tooling

Lifting Tools

Centralized Vaccume & Control System

Automized Heating System

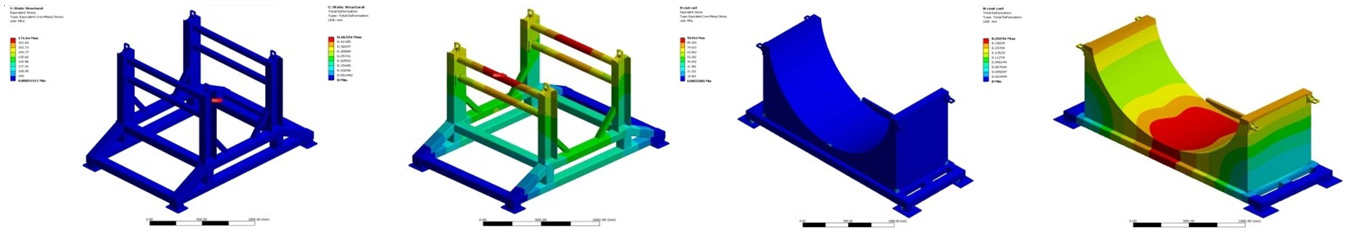

Structural Analysis / FEA Reports